We believed good quality of film can speak by itself in long term,We only start with the finest quality of raw material to achieve superior quality and consistency of the film, which is polyester.

Color Stability

In Raytech tint film manufacturer specialist, different color of film can be made on the film by deep dye process, this is process to embed the dye property within the film structure to make the color more durable and stable along the years.

Superior Performance

Clear Polyester film also can be coated with different metal to create superior solar control performance, the common process on this coating, called “vacuum metalizing” where thin layer of ATO (Alumina) coated onto the polyester film.

Variety

Clear Polyester film also can be coated with different metal to create superior solar control performance, the common process on this coating, called “vacuum metalizing” where thin layer of ATO (Alumina) coated onto the polyester film.

For Raytec high standard performance window films product, we merged one (1) to two (2) metalized layer and another layer of UV protection enhanced clear /dyed polyester films to offer most excellent performance of heat rejection and protect our customer from hazard ultra-violet (UV).

Quality Ensure

Our World-class Operation

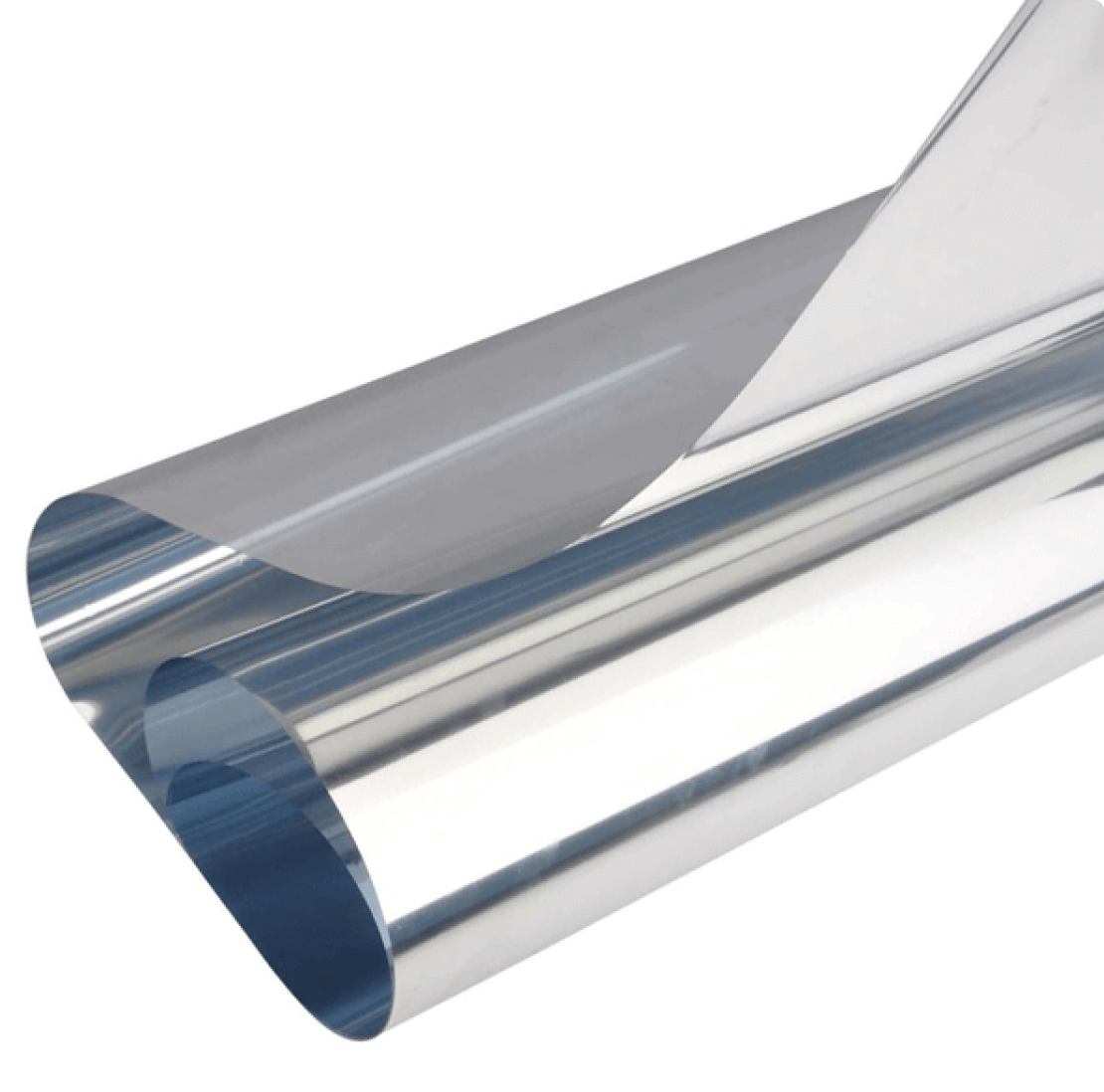

Electron Beam Films

Electron Beam metallised films from Raytech films are the state of the art solar control films that gives consumers the best of everything window films has to offer. Combining excellent heat rejection capabilities, beautiful aesthetics, fast drying time and ease of installation, it is the dream window films for most installers and consumers alike.

Raytech’s Electron Beam films are constructed using 2 ply of polyester but the darker shades of 5% and 10% are made using 3 ply of polyester. The double layers of metallised films give the maximum heat rejection possible while maintaining the natural aesthetics of your glass.

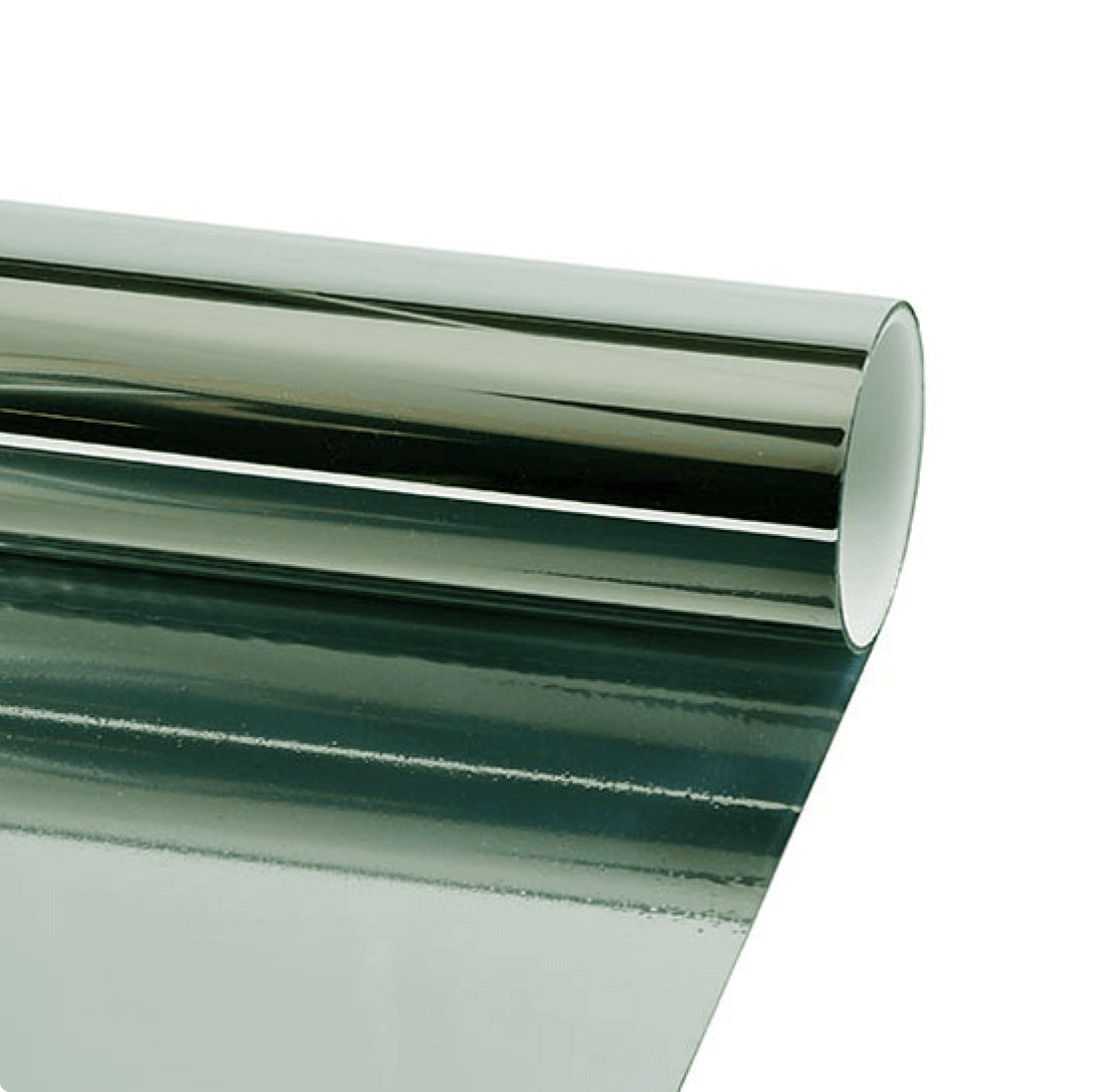

Sputtering film

Sputter films are manufactured by uniformly deposit various metal alloys onto a layer of high clarity polyester film in a large vacuum chamber of sputtering machine. This forms a layer of highly durable sputter coating that is excellent in heat rejection and low in reflectivity.

Those specific metals which widely use in manufacture sputtering films are commonly aluminium, silver, nickel, titanium, chrome, stainless steel, copper and other alloy. These metals provide good heat rejection and are very stable by nature. This helps to eliminate the possibility of metal oxidation within the film.